2024

Climate Change Response and Energy Management

In response to global climate change and the accelerating energy transition, TCL Tech. takes a proactive approach to environmental responsibility. We are committed to green, low-carbon development and strive to align our operations with environmental sustainability through innovation and integrated resource management.

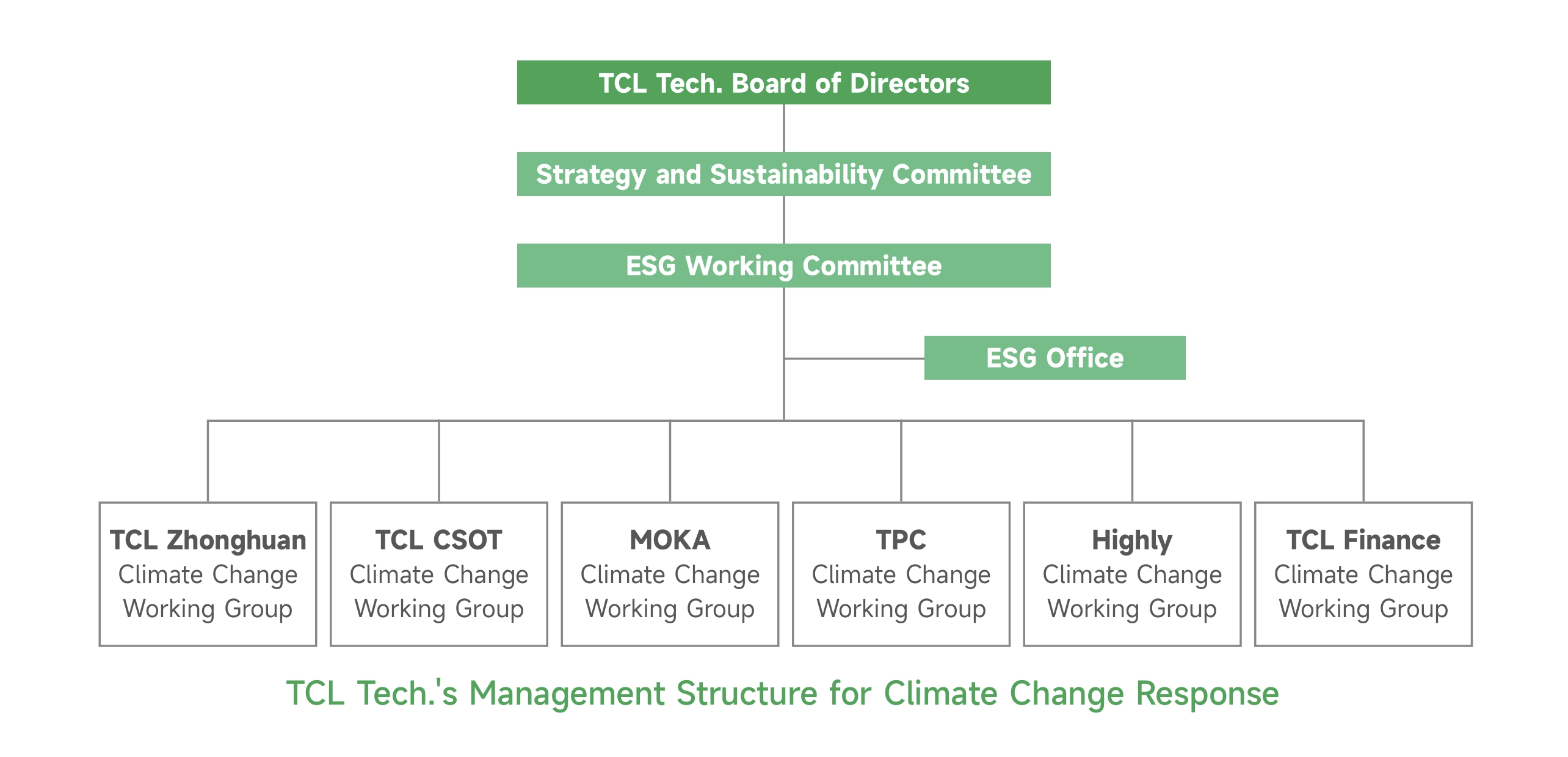

Improve the climate governance system

TCL CSOT’s Suzhou Base Joined the SBTi(Science Based Targets initiative)

TCL Tech. Launched the "Carbon Footprint Ledger" Digital Management Platform

TCL CSOT Energy Storage Power Station Project

Huansheng Solar, a Subsidiary of TCL Zhonghuan, Presented Sand Control and Wasteland Rehabilitation Solutions at the UNCCD COP16

Opportunities in Clean Technologies

At TCL Tech., investment in clean technology is a strategic priority. Building on our progress in this field, we continue to launch environmentally friendly products that support a low-carbon future and promote long-term sustainable development.

TCL CSOT launched the Industry's First Green All-in-One Device with Degradable PCB

MOKA's DT653K Monitor Earned Environmental Certification

Water Resources Management

TCL Tech. places great importance on water resource management, guided by the principles of conservation and efficiency. We implement region-specific, diversified measures to reduce water extraction and consumption in our operations, while strictly preventing water waste. Our goal is to achieve a consistent year-over-year reduction in water intensity across all production activities.

TCL CSOT Water Risk Identification and Assessment

Guangzhou CSOT, a Subsidiary of TCL CSOT, Officially Recognized as a 2024 Guangzhou Water-Saving Enterprise

All bases under TCL CSOT adopted water recycling measures.

Environmental Compliance and Ecological Protection

TCL Tech. places strong emphasis on stakeholders' concerns related to environmental compliance and ecological protection.

Guangzhou CSOT Recognized as a "Green Factory" and "Green and Low-Carbon Development Award"

TCL CSOT Wetland Park

TCL Zhonghuan's Subsidiary Zhonghuan Applied Materials Conducted Environmental Training for Suppliers

Pollutant Management

TCL Technology integrates pollutant management as a pivotal element of environmental stewardship, demonstrating its green manufacturing commitment through concrete actions.

In 2024, TCL CSOT's Wuhan Star was awarded the "Benchmark Enterprise for Pollutant Discharge Permit Management" by Wuhan City.

TCL Zhonghuan expanded its EPI acidic wastewater reuse system

Resource Recycling and Waste Management

TCL Tech. explores building a model base for industrial waste management. The goal is to set a benchmark for large enterprise groups and lead the industry in developing a zero-waste circular economy.

UL 2799 Zero Waste to Landfill certificate